Expert Metal Fabrication Solutions: Mastering High Pressure Die Casting Moulds at DeepMould.net

In the dynamic landscape of modern manufacturing, the demand for precision-engineered components and efficient production methods continues to grow exponentially. At the core of this evolution lies the groundbreaking technology of high pressure die casting moulds. Companies like DeepMould.net have established themselves as industry leaders, delivering innovative metal fabrication solutions that harness the power of this advanced casting process.

Understanding the Significance of High Pressure Die Casting Moulds

High pressure die casting](https://deepmould.net) is an esteemed manufacturing method that involves forcing molten metal into a meticulously crafted mould under high-pressure conditions. The moulds used in this process are critical, as they define the final product's quality, dimensional accuracy, surface finish, and structural integrity.

This technique is predominantly employed in producing complex, high-volume metal parts for industries such as automotive, aerospace, electronics, and consumer goods. The high pressure die casting mould must withstand immense operational stresses while maintaining tight tolerances through countless cycles, making its design and manufacturing a sophisticated art and science.

The Critical Role of Precision and Durability in Mould Manufacturing

For a metal fabricator like DeepMould.net, the focus extends beyond simply creating a mould. It involves engineering high pressure die casting moulds that deliver impeccable performance, durable longevity, and repeatable precision. A high-quality mould results in products with minimal defects, reduced scrap rates, and overall enhanced production efficiency.

Key Attributes of Superior High Pressure Die Casting Moulds

- High-Temperature Resistance: To withstand the molten metal's extreme heat without deformation or degradation.

- Wear Resistance: Ensuring longevity over thousands of casting cycles.

- Dimensional Accuracy: Maintaining tight tolerances essential for high-precision components.

- Complex Geometries Capability: Allowing intricate designs that meet contemporary industrial demands.

- Ease of Maintenance: Facilitating quick repairs or modifications to minimize downtime.

The Manufacturing Process of High Pressure Die Casting Moulds at DeepMould.net

DeepMould.net employs a comprehensive, multi-phase approach to creating high pressure die casting moulds. This meticulous process ensures each mould meets stringent quality standards and tailors precisely to client specifications.

Design Phase: Precision Engineering and Simulation

Designing a high pressure die casting mould begins with detailed Computer-Aided Design (CAD) models. Engineers leverage advanced simulation tools to optimize the mould's structure, ensuring optimal metal flow, heat dissipation, and durability. This phase allows for preemptive identification of potential issues, significantly reducing costly revisions during production.

Material Selection and Procurement

The choice of materials for the mould is pivotal. DeepMould.net uses premium-grade steel alloys such as H13, P20, and S7, which offer excellent thermal stability, machinability, and resistance to wear. These materials are procured from trusted suppliers to ensure consistency and reliability.

Machining and Fabrication

Advanced CNC machining centers are employed to precisely shape the mould components, adhering to the detailed CAD specifications. DeepMould.net's skilled machinists utilize a combination of milling, EDM (Electrical Discharge Machining), and grinding to achieve complex geometries and fine surface finishes.

Heat Treatment and Surface Finishing

Post-machining, the mould undergoes heat treatment processes such as hardness induction and tempering to enhance resilience. Surface treatments including polishing, coating, or nitriding are applied to improve performance and lifespan.

Assembly and Testing

The final assembly involves precision fitting of all components, ensuring seamless operation. Experimental trial runs simulate actual casting conditions to verify mould integrity, metal flow, and product quality. Any necessary adjustments are made before delivery.

Innovation and Technological Advancements in Mould Manufacturing

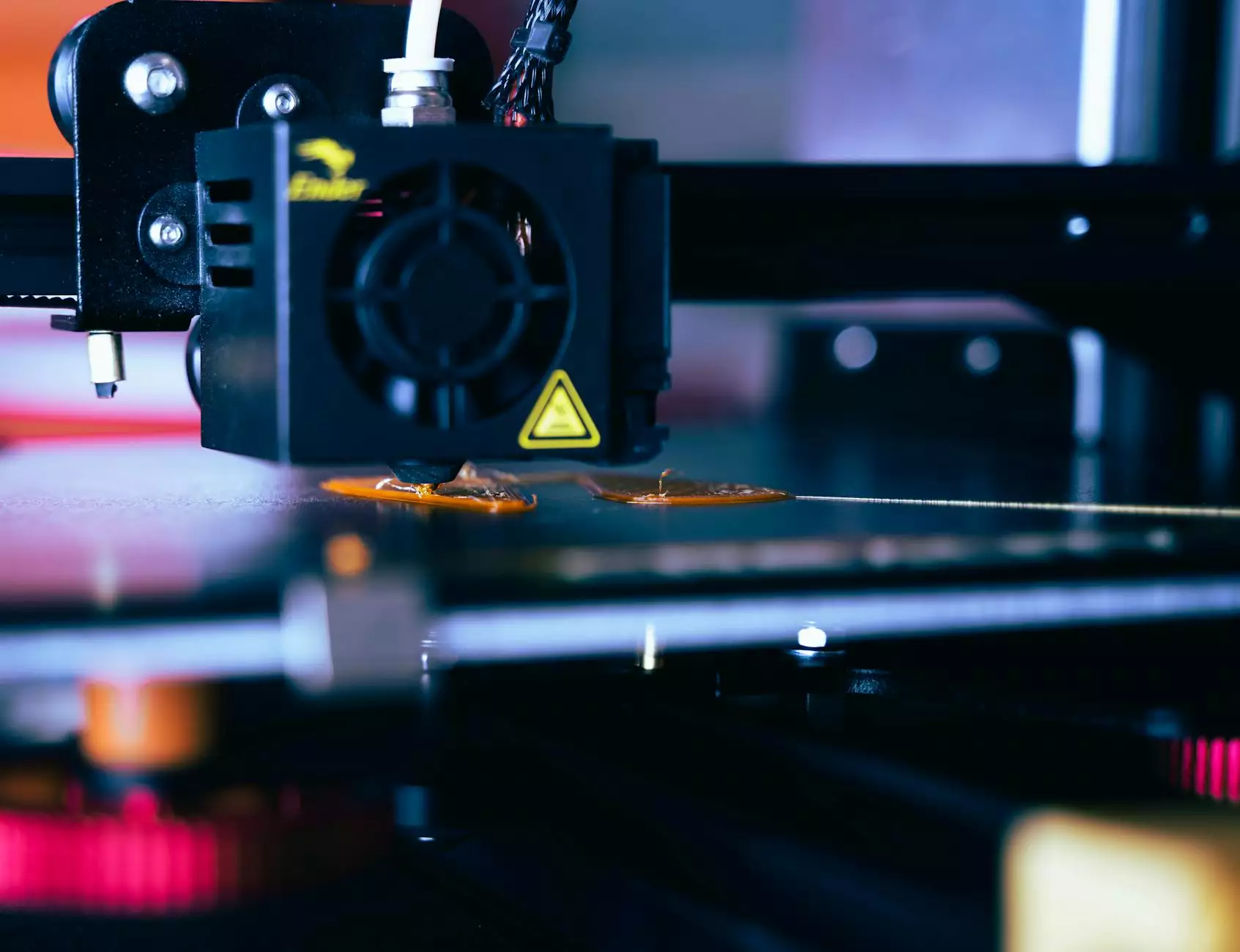

DeepMould.net stays at the forefront of technology by integrating innovative techniques such as Additive Manufacturing (3D printing) for prototype development, CNC high-speed machining for rapid production, and evolutionary die design software for optimizing mould performance.

Furthermore, the adoption of digital twins enables simulation and real-time monitoring of moulds throughout their lifecycle, preventing failures and extending operational lifespan. This continuous innovation helps clients achieve faster time-to-market, cost savings, and higher product quality.

The Advantages of Partnering with DeepMould.net for Your High Pressure Die Casting Mould Needs

Choosing DeepMould.net as your trusted metal fabricator provides several key benefits that elevate your manufacturing process:

- Exceptional Quality Control: Rigorous inspections and testing protocols guarantee mould perfection.

- Customization Capabilities: Tailored design solutions to meet specific project requirements.

- Advanced Technological Infrastructure: State-of-the-art facilities ensure precision and efficiency.

- Fast Turnaround and Delivery: Efficient project management minimizes lead times.

- Competitive Pricing: Cost-effective solutions without compromising quality.

- Expert Technical Support: Ongoing customer engagement and technical consultation.

Applications and Industry Impact of High Pressure Die Casting Moulds

The applications of high pressure die casting moulds are vast and transformative. They contribute significantly to sectors demanding high precision, durability, and complex shapes:

- Automotive Industry: Manufacturing engine blocks, transmission housings, and structural components.

- Aerospace: Producing lightweight yet robust parts such as cabin fittings and structural panels.

- Electronics: Creating enclosures, connectors, and intricate internal components.

- Consumer Goods: Developing appliances, housings, and decorative elements.

- Industrial Equipment: Fabricating machine frames, handles, and specialty industrial parts.

By employing high pressure die casting with expertly crafted moulds, manufacturers can drastically enhance product quality, reduce waste, and accelerate production timelines, providing a formidable competitive advantage.

Maintaining Excellence: Lifecycle Management of High Pressure Die Casting Moulds

Quality and performance do not end at the manufacturing stage. DeepMould.net emphasizes lifecycle management by offering:

- Routine Maintenance Services: Cleaning, surface treatments, and minor repairs to prolong mould lifespan.

- Reconditioning and Reengineering: Upgrades and modifications to adapt to new product designs.

- Monitoring and Inspection: Using advanced tools like CMM (Coordinate Measuring Machine) for precise assessments.

Implementing a comprehensive lifecycle approach ensures ongoing excellence, minimizes unscheduled downtime, and secures long-term ROI for manufacturing partners.

Why DeepMould.net Reigns Supreme in Metal Fabrication for Die Casting

With decades of experience, a highly skilled engineering team, and a customer-centric philosophy, DeepMould.net has positioned itself as a leader in the field of metal fabrication specializing in high pressure die casting moulds. Their commitment to innovation, quality, and sustainability makes them a dependable partner for complex projects across industries.

"DeepMould.net’s precision-engineered moulds have revolutionized our production line, delivering unmatched quality and efficiency." – Satisfied Client

Conclusion: Unlocking Manufacturing Excellence with High Pressure Die Casting Moulds

In today’s competitive industrial landscape, the importance of a reliable, high-precision high pressure die casting mould cannot be overstated. It is the foundation upon which superior metal parts are built, ensuring that your products meet or exceed quality standards while maintaining cost-effectiveness and efficiency.

Partnering with a reputable metal fabricator like DeepMould.net offers you access to state-of-the-art technology, expert craftsmanship, and comprehensive support services designed to optimize your manufacturing outcomes.

Elevate your production capabilities today by investing in precision-engineered high pressure die casting moulds. Experience enhanced product quality, reduced operational costs, and an accelerated pathway to market leadership.